Okay, I get it, I'm not the sharpest stick in the woodshop. I was making this ridiculously simple chair and we needed to round out some corners. Toby, who was working with me, took a brand new blade and popped it into a jigsaw and I cut away. I tried to turn the corner as I powered through the material but I cut too wide. And then to compound the error I did it again. Okay, I get it, I'm not the sharpest stick in the woodshop. I was making this ridiculously simple chair and we needed to round out some corners. Toby, who was working with me, took a brand new blade and popped it into a jigsaw and I cut away. I tried to turn the corner as I powered through the material but I cut too wide. And then to compound the error I did it again.

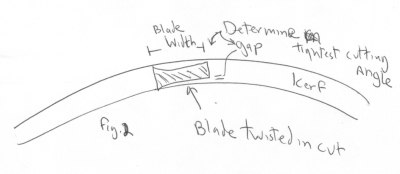

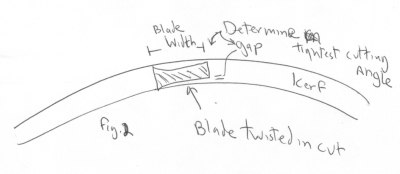

The reason is that I'm stupid. The right way to cut a tight curve is use a narrow blade. A wider blade won't work even if you try to cut slowly. A saw can cut a curve because if you twist the blade in the cut it will turn the amount possible given the width of the blade and the width of the actual kerf of the saw cut (fig. 2). The wider the blade the less of an angle you can twist and that's the limiting factor. That's why our bow saw blades are only 1/8" wide - it's so you can turn on a dime. Wider blades are better for tracking straight.

We got the idea for 1/8" wide bow saw blades for our turning saw when we saw the blades on Duncan Phyfe's turning saw. He used 1/4" material - but for the working length of the saw blade - the blade was ground narrower to maybe 3/16". We got the idea for 1/8" wide bow saw blades for our turning saw when we saw the blades on Duncan Phyfe's turning saw. He used 1/4" material - but for the working length of the saw blade - the blade was ground narrower to maybe 3/16".

So, if you you want to cut a curve, don't do what I did - get a narrow blade - hand or power. Otherwise you need another strategy.

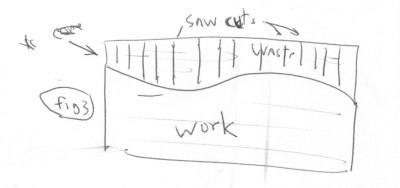

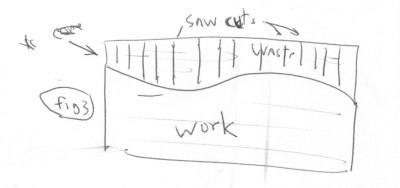

Another strategy that works is to cut a series of straight saw cuts perpendicular to the final curve (fig. 3) and then cut knock out the waste with a chisel. Then work the curve smooth with rasps or a spokeshave. Another strategy that works is to cut a series of straight saw cuts perpendicular to the final curve (fig. 3) and then cut knock out the waste with a chisel. Then work the curve smooth with rasps or a spokeshave.

Here's an old blog entry I wrote years ago about special blades for cutting curves with a circular saw.

Note: I have realized that lately I'm spending a lot of time about what happens with things go wrong. The reason for this might be is that when things go right I don't think twice about it and I don't see the blog entry in it. Of course another possibility might be that banging my head against the wall is just the story of my life and I need to write about it.

|

Joel's Blog

Joel's Blog Built-It Blog

Built-It Blog Video Roundup

Video Roundup Classes & Events

Classes & Events Work Magazine

Work Magazine

We got the idea for 1/8" wide bow saw blades for our turning saw when we saw the blades on

We got the idea for 1/8" wide bow saw blades for our turning saw when we saw the blades on  Another strategy that works is to cut a series of straight saw cuts perpendicular to the final curve (fig. 3) and then cut knock out the waste with a chisel. Then work the curve smooth with rasps or a spokeshave.

Another strategy that works is to cut a series of straight saw cuts perpendicular to the final curve (fig. 3) and then cut knock out the waste with a chisel. Then work the curve smooth with rasps or a spokeshave.

My 8 year old woodworking student had to to cut a curve on his project and the curve was made in 2x4 material. The tool he had to use was a jig saw with a wide blade. He had never used a jigsaw before although he did have one previous lesson on a scroll saw. I taught him the method of cutting a short distance then backing the tool up and cutting again. That way the wide blade creates its own wide path. He cut a nearly perfect, very smooth curve. Not bad for an 8 year old who has only two months of one hour lessons on a Saturday.

Every time I hear someone putting an 8 year in the shop I am thrilled. Congratulations to you on not being scared that your child is too young!!. Too many people are afraid of letting kids into the shop - even with tons of supervision.

Sadly, however - your technique would not have worked in my case as I needed both sides of the cut and did I mention that I had narrow blades around I just didn't think to you them. When I tell you I was being pretty stupid I was not exaggerating.

The smoothest radius cut comes from when you happen to find the perfect sized saw blade and can "ride" the back of the blade in the kerf - helps keep your trajectory smooth if you aren't quite perfect at steering.